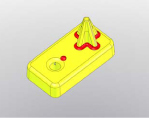

A number of years back I needed to make a simple change to a simple part. The part was injection molded which meant that a change to the part required a change to the tool. Typically, I would send the new STL file to the mold maker and explain the changes in an e-mail. They would plug the STL file into their software, analyze the changes and provide a quote for the modifications. In this particular case I highlighted the changes in red color, printed a model and handed it to the mold maker. Even simple changes to an injection molded part can require complicated tooling changes depending on where cooling lines, ejector pins, rings, and gates are located. Having the actual part with highlighted changes helped the tool maker quickly understand what it would take to successfully modify the tool. A picture of this part, used in our 3D Printers, is shown below.

I recently visited a Z Corp. customer who uses a ZPrinter®650 in a similar way. He frequently uses multiple colors to identify different fabrication processes required to complete a part. His parts are complicated shapes from exotic materials. For example, he will highlight the first process with one color, a second process with another color and might add a third or fourth color to show other areas of interest on the part. Because the parts are so complicated and expensive, poor communication can lead to costly mistakes. His main purpose for creating color models is to improve communication throughout the design and fabrication process.

Thanks...

ReplyDelete3d printed products